Initially, our minimum order quantity was 200 pairs, but we also received many inquiries for orders of 30 or 50 pairs. Customers told us that no factory was willing to take such small orders. To meet the needs of these entrepreneurial customers, we adjusted our production line, lowered the minimum order quantity to 50 pairs, and offered customization services. Some might ask why we went to such great lengths to adjust our factory production line just to meet small-batch orders. Over 30 years of industry experience has taught us that overstock is the biggest killer in the footwear industry. A wide variety of stock-keeping units (SKUs) in various styles, sizes, and colors can quickly drain an entrepreneur's capital. To lower the barrier to entry for customized men's leather shoes and make entrepreneurship more accessible, we adjusted our production line.

How LANCI Masters Small Batch Customization (50-100 Pairs)

"We built our factory for your vision, not just for production."

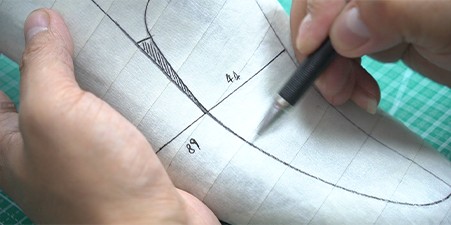

Hybrid Process: Combining Hand Cutting (Flexibility) with Machine Precision (Consistency).

This is the most crucial step. Many traditional men's shoe factories can't handle small-batch customization because they use molds and machines to cut leather, which lacks flexibility. They consider 50 pairs of shoes a waste of effort. Our factory, however, uses a combination of machines and manual labor, ensuring both precision and flexibility.

The DNA of Small-Batch Customization: Every artisan and every process is optimized for agility.

Since deciding that our factory would offer small batch customization, we've optimized every production line and trained every artisan. 2025 marks our third year of small-batch customization, and every artisan is familiar with our production method, which differs from other factories.

A Waste-Controlled Workflow: Carefully Selected Leather + Intelligent Patternmaking → ≤5% waste (traditional factories have a waste rate of 15-20%).

Our factory understands that starting a business is incredibly demanding, both physically and financially. To help our customers save even more, we pay special attention to leather cutting, calculating each cut to minimize waste. This not only saves costs but is also environmentally friendly.

Craftsmanship, not assembly lines: Our team is dedicated to unique projects. Your 50 pairs of shoes will receive meticulous attention.

By 2025, our factory has served hundreds of entrepreneurs, and we understand their priorities. Whether you're facing early-stage challenges or struggling with quality at the factory, we can provide you with effective solutions. Confidently choose us.

Custom Leather Shoe Branding Process

1: Start With Your Vision

2: Choose Leather Shoe Material

3: Customized Shoe Lasts

4: Build Your Brand Image Shoes

5: Implant Brand DNA

6: Check Your Sample Through Video

7: Iterate To Achieve Brand Excellence

8: Send The Sample Shoes To You

Start Your Custom Journey Now

If you are running your own brand or scheduling to create one.

LANCI team is here for your best customization services!